Advantages of Using Electronic Batching Weighing Feeder

At present, the working efficiency has also been improved a lot in the bulk material production batching field as well as transportation equipment field by adotping the automatic weighing feeding system.In addition,the quality and efficiency of the batching is also more and more high. In the process of bulk material transfer feeding with conveying, measuring, especially automatic weighing feeder function equipment has been more and more widely used.

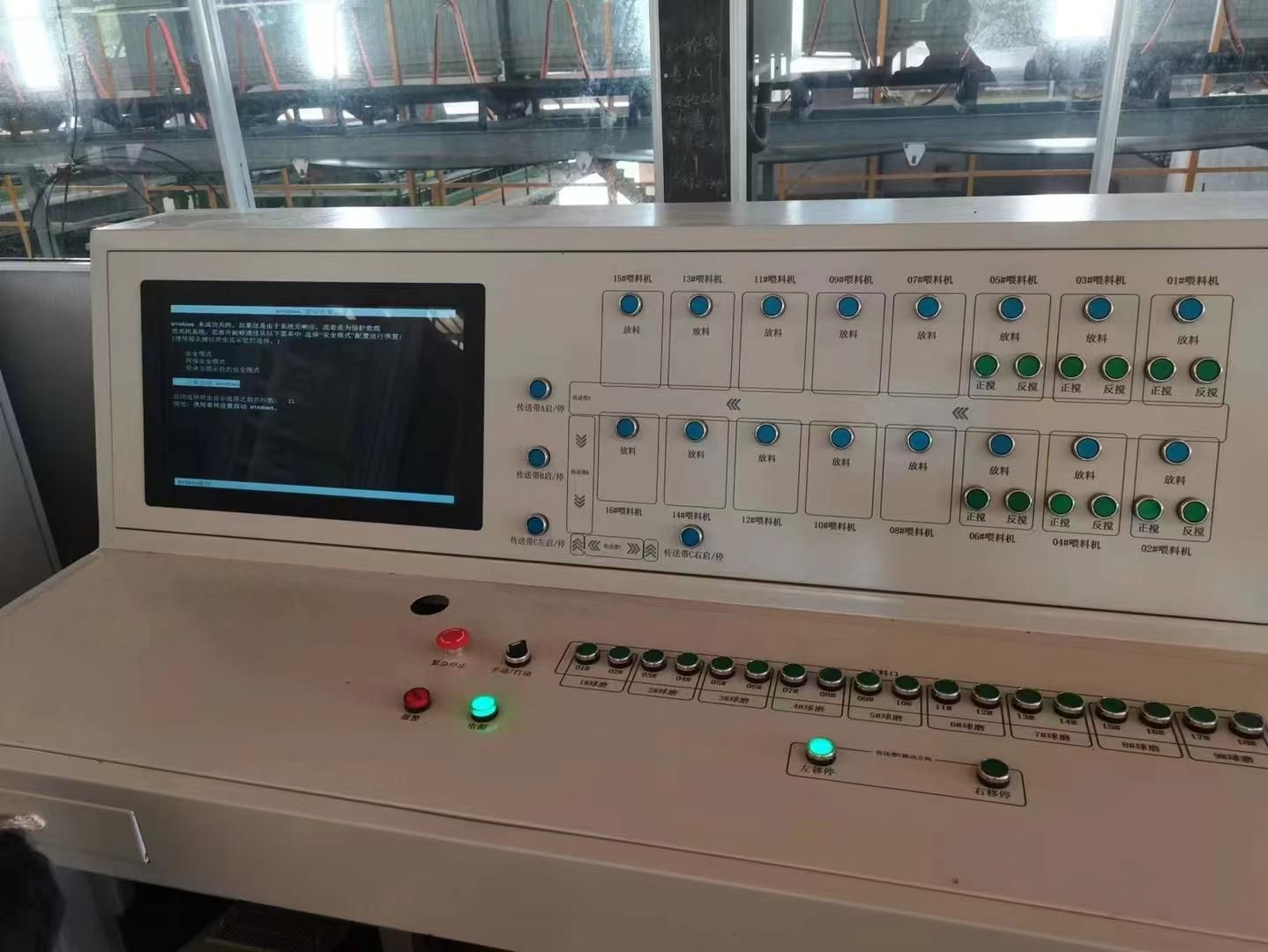

The electronic weighing feeding scale is automatic bulk material batching measuring and feeding equipment and it makes use of intelligent quantitative weighing of bulk material conveying capacity.At the same time it has quantitative dynamic, continuous measurement function, coupled with PLC control function which has been applied in many fields of industrial bulk material and has played an important functional role.

Electronic weighing feeding scale machine has the characteristics of easy to use, easy to operate, easy to maintain, high work efficiency, high degree of automation and information technology, which is suitable for building materials, metallurgy, mining, chemical industry and other industries. It is suitable for various characteristics of the bulk material, granular, powder, block and so on can be applied.

It is an important function of the electronic feeding scale feeder by quantitative control according to the actual needs of the application .It can automatically adjust the material flow according to the established parameters in the system, through intelligent control and PLC control system, to ensure that the given material flow has been consistent with the system parameters. At the same time, it is also very simple in operation. The three-color light alarm control mode can decentralize the feeding amount of each material, and carry out centralized control settings and other operations to facilitate the application of field operation management. Therefore, in the systematic application of industrial bulk materials, it can not only be used for the batching of bulk materials, but also can be used for quantitative control loading (loading) system in all kinds industry areas.

The electronic feed feeder can be used in the automatic batching control system of bulk materials. Batching in industrial production is the process of feeding and mixing various bulk materials according to the formula. Multiple electronic feeders deliver different materials for continuous conveying and dynamic weighing. At the same time, each material is fed according to the formula of the system, so as to complete the feeding and then mixing. The feeder can complete automatic batching of bulk materials in various industries, such as automatic batching of cement production line.

Whether in the batching system or loading system of the application, the electronic feeding scale feeder has highlighted its advantages, a high degree of automation, no manual weighing, feeding or loading, improve operational efficiency, reduce operating costs, save time and effort. In addition, the electronic scale feeder applied network information and computer software technology, while the operation can provide users with real-time data, both through the instrument display, query, can also be remote query. These real-time and historical data and reports provide support for users to improve the efficiency and quality of production management and optimize production.

In short, in the field of industrial bulk material, the electronic feeding scale has an irreplaceable position and it has an important application in the high bulk material batching loading system which can be said to be the core equipment.