Application

Application in Industry Fields

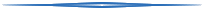

Automatic batching of metallurgical production lines

Automatic batching of cement production lines

Automatic batching of rubber production line

Automatic batching in the mixing station

Automatic batching of compound fertilizer production line

Automatic batching of alloy material production line

Automatic batching of ferrosilicon production line

Automatic control of lime kiln ingredients

Coking production produces automatic ingredients

Plastic calendering production line for metering ingredients

Automatic batching of biological production lines

New energy battery production line automatic batching and so on

What is Automated Batching System

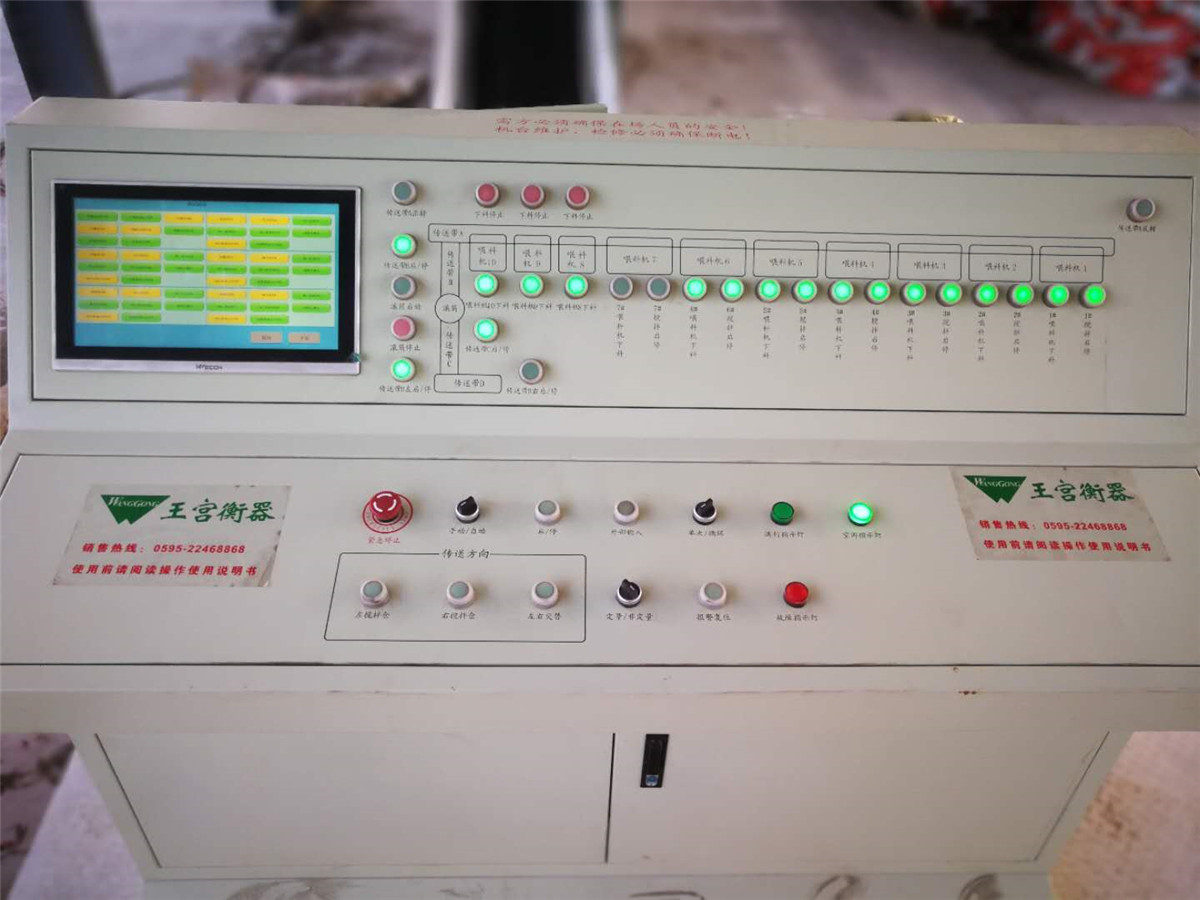

Automated batching system is a kind of batching system for automated industrial production, usually by a computer with automatic batching algorithm software as its automatic batching control system. Automated batching system can control multiple scales at the same time, a variety of different materials or control output operations with intuitive, clear, automatic recovery function; powerful report function, can record and store a large number of types of data and tabulation printing; good reliability; powerful alarm prompt function, can reduce the error rate to the minimum; equipped with online automatic monitoring software, through real-time online monitoring, monitor important information of production at any time .

Over- controlled traceability system:

Starting from the source, the control of key processes such as raw materials, ingredients, feeding, packaging, and shipping in the production process has changed from postpartum detection in the past to prenatal, in-production control and post-production traceability, so as to ensure that the production is done correctly once and the quality is traced one yard .

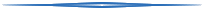

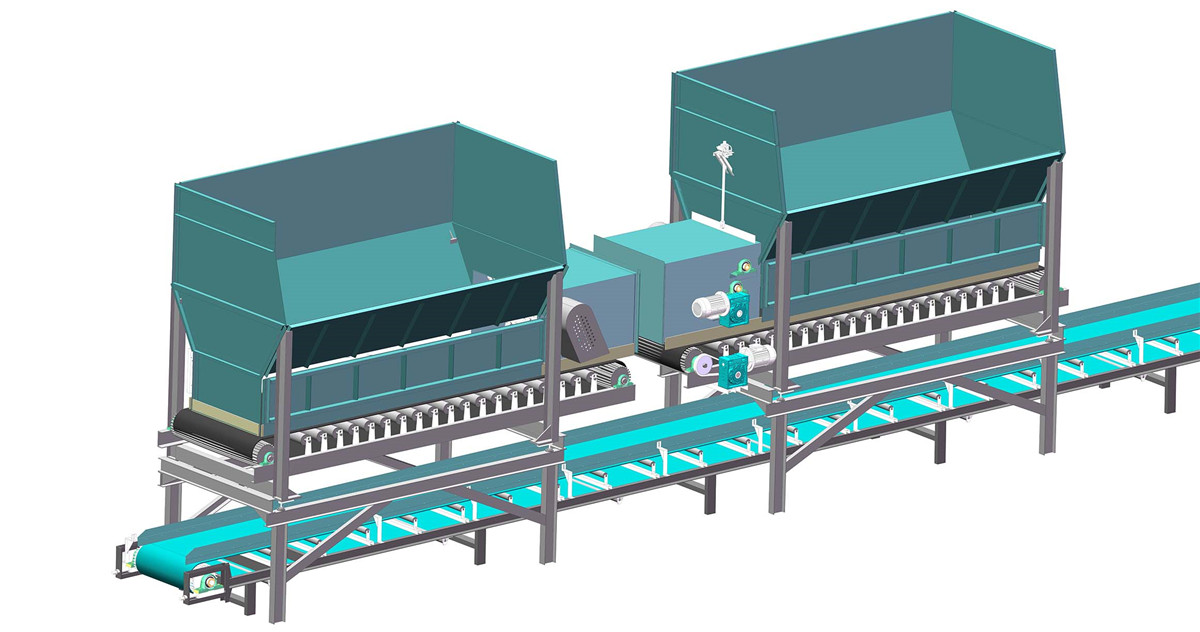

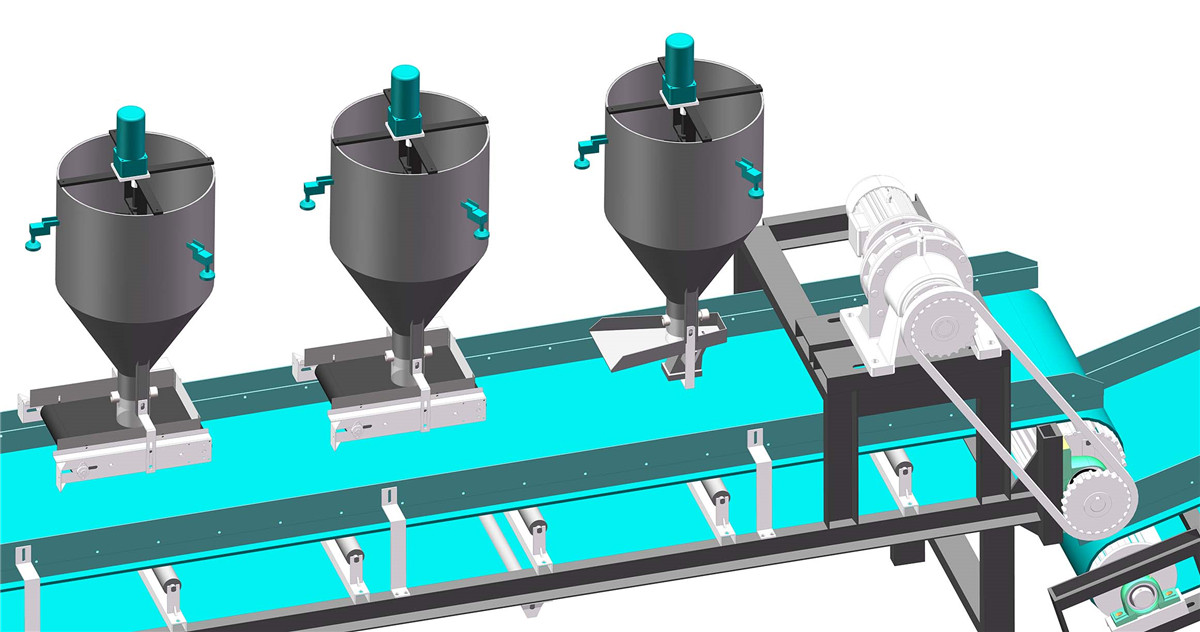

According to the customized demand soft control research and development of high-precision, high-efficiency, highly automated soft or hard material batching equipment, according to the production formula, the required various ingredients according to the set weight and precision automatic ratio, can help users improve quality, reduce production costs, improve the working environment to improve the quality of ingredients efficiency.

Weighing system:

It is used to solve the problems of possible mismatch, under-allocation, and low weighing accuracy of manual ingredients to ensure accurate and complete weighing. Help users improve product quality, reduce waste, and accurately calculate material consumption.

Easy to operate, reducing reliance on skilled ingredient workers.

Upper auxiliary system:

Designed for the rubber and plastic, tire industry, automatic conveying, batching, feeding system of powder, oil and rubber. The use of automation control, software information technology, to achieve the integration of control, industrial informatization.Use the upper auxiliary machine system to improve quality and efficiency and improve the environment.

Advantages of batching sytem:

Industrial control soft control industry solutions, to help enterprise lean production, explore the development trend of the industry, help enterprise lean production, win new business growth .

Use automatic ingredients to improve quality and efficiency " The amount of ingredients is large, dirty and tired, especially in the summer, workers are more reluctant to work, and it is difficult to recruit workers. After using automatic ingredients, it saves people and is accurate .

Over-control traceability Mes makes the production right once, and the quality is traced one yard " The product quality is produced, not tested .

The use of auxiliary machines to improve quality and efficiency, improve the environment "accurate measurement, save people, the workshop is also clean."

Market Demand

Ingredients is a very important process in the production process of industrial enterprises, the quality, efficiency and stability of the batching process plays a pivotal role in the entire industrial production process and the quality of the product, the backward ingredient system is not only inefficient and inaccurate, manual operation of ingredients and the introduction of human factors into the batching link, seriously affecting the stability and further improvement of product quality, and has a large labor intensity, lack of labor protection, environmental protection is not up to standard and other defects, Hand-made ingredients make it difficult for industrial formulations to be realized in large-scale industrial production. Therefore, high-precision and intelligent batching systems are of great significance to industrial enterprises.

The important role of China's rapidly growing "global manufacturing plant" and the relatively backward industrial intelligent batching system industry have formed a huge contradiction and market opportunities, making the domestic intelligent batching system market a global competitive market, but also attracting domestic capital inflows, have increased investment in the industrial intelligent ingredients industry, and actively opened up the domestic market.

Intelligent batching control technology is widely used such as electrical control technology, measurement technology, sensing technology, computer software technology, mechanical technology, materials and chemical technology and other multi-disciplinary, multi-faceted professional technology, intelligent batching control technology is mainly used in industrial production enterprises raw materials, auxiliary materials measurement, transportation, storage and feeding and other aspects of the link.

Solve Markets Needs

High-performance automated batching system with features and practical functions are indispensable. The high performance of a set of systems can be composed of many aspects, such as through high-performance programmable control, the host computer can be used for formula management, screen man-machine and weighing data storage query printing and other work, to achieve the automation of ingredients, and weighing instruments can assume the heavy responsibility of the "brain", no longer a simple calculation display function, with self-diagnosis, automatic zero tracking, zero peeling, dynamic weighing, data communication and other functions, and then improve the accuracy while strengthening the automation of batch control.

In the face of complex and changeable formulas and a variety of different material ingredients, the automatic batching control system can flexibly adjust a variety of ingredient ratios according to the customer's actual formula and production process, and the customer only needs to complete the parameter setting on the host computer.

Different customers' site there are environmental differences, affected by the environment changeable, harsh, dust and many other factors, the material may appear under the influence of temperature, humidity under the influence of some thorny problems, the batching control system can choose the right conveying and metering equipment according to the material, such as spiral feeder, belt conveyor can increase the sealing structure, which can not only improve the optimization of the production environment, but also prevent material spillage, avoid material waste, while playing a certain protective role for materials.

Wanggong Technology intelligent batching control system, a can solve the on-site batching control problems, customized software management system, measurement control data, real-time upload display to the superior management department, generate visual data reports, help managers remotely monitor production, provide data support for scientific production scheduling decisions, at the same time, the system can set different levels of operation authority, further ensure the security of data, prevent human fraud, and protect the security of enterprise production data.